2018 wholesale price Twill Carbon Fiber - Silver Carbon Fiber Cloth – Chengyang

2018 wholesale price Twill Carbon Fiber - Silver Carbon Fiber Cloth – Chengyang Detail:

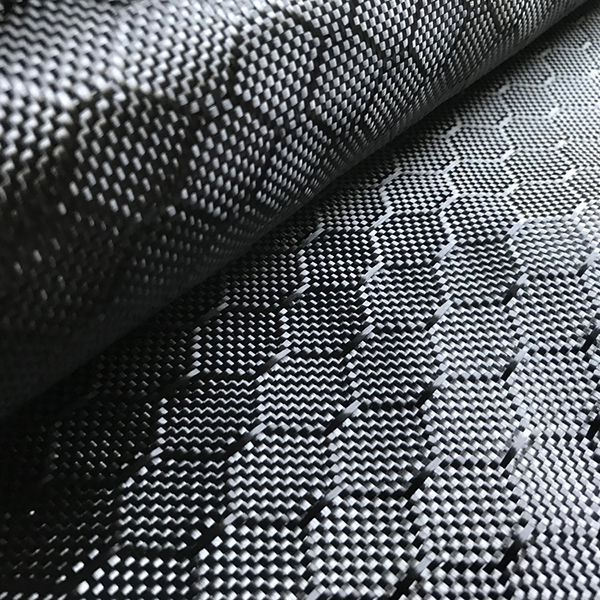

Silver Carbon Fiber Cloth

Features

Advantages of Carbon Fiber

Carbon fiber composites stand out from the crowd for several reasons. Here are a few:

1.Lightweight – carbon fiber is a low density material with a very high strength to weight ratio

2.High tensile strength – one of the strongest of all commercial reinforcing fibers when it comes to tension, carbon fiber is very difficult to stretch or bend

3.Low thermal expansion – carbon fiber will expand or contract much less in hot or cold conditions than materials like steel and aluminum

4.Exceptional durability – carbon fiber has superior fatigue properties compared to metal, meaning components made of carbon fiber won’t wear out as quickly under the stress of constant use

5.Corrosion-resistance – when made with the appropriate resins, carbon fiber is one of the most corrosion-resistant materials available

6.Radiolucence – carbon fiber is transparent to radiation and invisible in x-rays, making it valuable for usage in medical equipment and facilities

7.Electrical conductivity – carbon fiber composites are an excellent conductor of electricity

8.Ultra-violet resistant – carbon fiber can be UV resistant with use of the proper resins

Application

Carbon fiber (also known as carbon fibre) is one of the strongest and most lightweight materials available on the market today. Five times stronger than steel and one third its weight, carbon fiber composites are often used in aerospace and aviation, robotics, racing, and a wide variety of industrial applications.

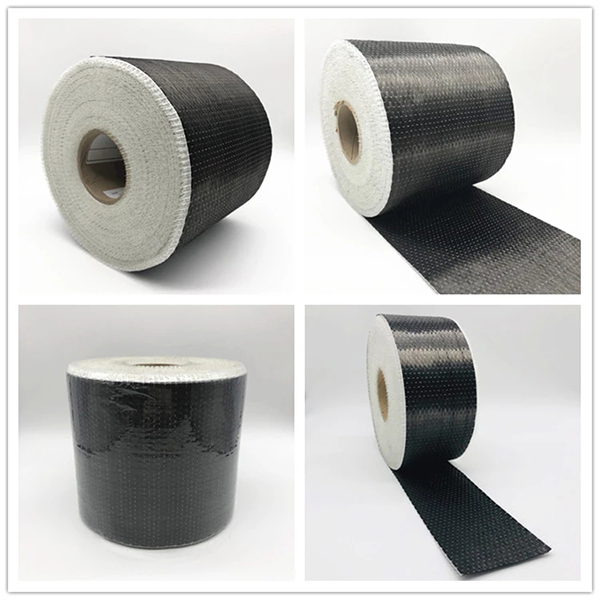

Maintenance after reinforcement

The natural maintenance time is 24 hours. To ensure that the reinforced parts are not disturbed and impacted by external forces, if it is outdoor construction, it is also necessary to ensure that the reinforced parts are not exposed to rain. After the construction, the reinforced parts can be put into use after 5 days of maintenance.

Specific requirements for construction safety

1. When cutting carbon fiber cloth, keep away from open fire and power supply;

2. Carbon fiber cloth materials should be stored in a sealed environment, avoid open fire, and avoid sunlight;

3. When preparing structural adhesive, it should be prepared in a well ventilated environment;

4. The construction site needs to be equipped with fire extinguisher to avoid timely rescue in case of safety accident;

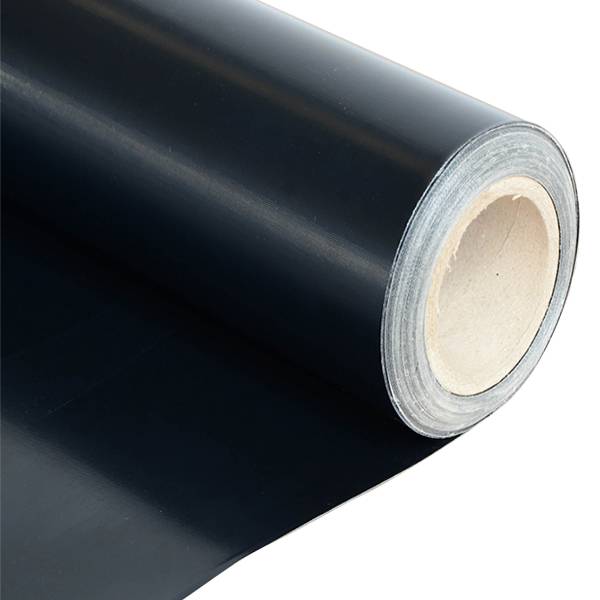

Product detail pictures:

Related Product Guide:

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for 2018 wholesale price Twill Carbon Fiber - Silver Carbon Fiber Cloth – Chengyang , The product will supply to all over the world, such as: Monaco, Indonesia, Mexico, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

1. What is MOQ?

10m2

2. What thickness of the PTFE fabric?

0.08mm,0.13mm,0.18mm,0.25mm,0.30mm,0.35mm,0.38mm,0.55mm,0.65mm,0.75mm,0.90mm

3. Can we print our logo in mat?

PTFE surface, also called ptfe, very smooth, not able to print anything in mat itself

4. What the package of the PTFE fabric?

The package is export carton.

5. Can you get the custom size?

Yes, we can offer you the ptfe fabric you desired size.

6. What is the unit cost for 100roll,500roll,including freight via express to the united states?

Need know how is your size, thickness and requirement then we can calculate the freight. Also freight varies every month, will tell right after your exact enquiry.

7. May we take samples? How much will you charge?

Yes, Samples which size A4 are free. Just freight collect or pay freight to our paypal account.

USA/West Euope/Australia USD30,South-East asia USD20.Other area, quote separtely

8. How long will it take to receive samples?

4-5days will make you receive samples

9. Can we pay for the samples via paypal?

Yes.

10. How long will it take to manufacturer once an order has been placed?

Normally will be 3-7days. For busy season, qty over 100ROLL or special delivery requirement you need, we will discuss separately.

11. What is your competivity?

A. Manufacture. Price competitive

B. 20years Manufacturing experience. China’s 2nd earilst factory in PTFE/silicone coated material production. Abundant experience in quality control and good quality garanteed.

C. One-off, small to medium batch production, small order design service

D. BSCI audited factory, bidding experience in large supermarket of USA and EU.

E. Fast, reliable delivery

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!