1, a production process of electronic glass fiber cloth, which is characterized by: including the following steps: wire drawing: first, appropriate infiltrating agent is configured to evenly form a film on the original wire; Yarn knot, yarn knot process includes: twist (initial twist), batch warping (or combined warping), parallel shaft sizing, warp threading, air jet weaving.

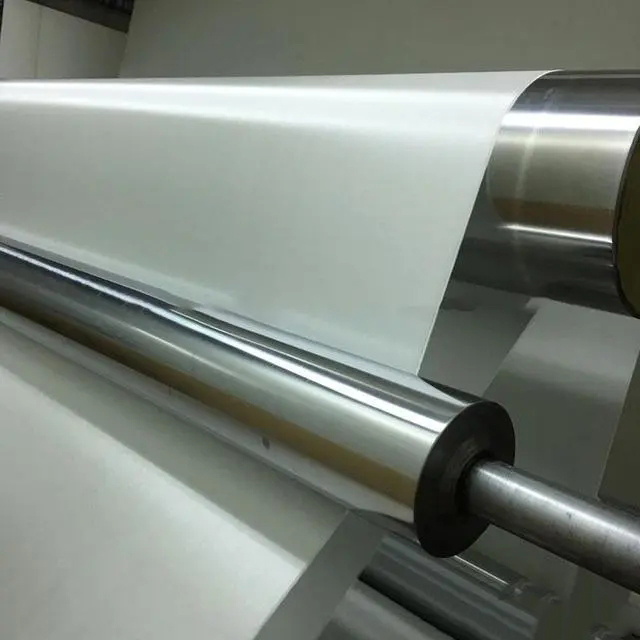

2, post-treatment, post-treatment process includes: continuous heat treatment, batch heat treatment, surface chemical treatment; Drying roll into cloth roll, after inspection and packaging to get glass fiber cloth.

3. According to the production process of electronic glass fiber cloth mentioned in Claim 1, its characteristics are as follows: in step A, most of the wire drawing infiltrating agent is modified starch type, and the original wire number is 6817 tex.

4. According to the production process of electronic glass fiber cloth mentioned in Claim 1, its characteristics are as follows: in step B, modified starch size is used to size yarn in the batch warping process.

5. According to the production process of electronic glass fiber cloth mentioned in Claim 1, its characteristics are as follows: in step C, high temperature depulsing furnace is used for continuous heat treatment and batch heat treatment. The temperature of continuous heat treatment furnace is controlled at 420-465℃, and the temperature of batch heat treatment is controlled at 400-430 ℃.

6. According to the production process of electronic glass fiber cloth mentioned in Claim 1, its characteristics are as follows: the surface chemical treatment of the glass fiber cloth is treated with silane treatment agent.

https://www.heatresistcloth.com/

Post time: Oct-12-2022