OEM manufacturer Carbon Fibre Cloth Suppliers - Purple Carbon Fiber Fabric – Chengyang

OEM manufacturer Carbon Fibre Cloth Suppliers - Purple Carbon Fiber Fabric – Chengyang Detail:

Product introduction

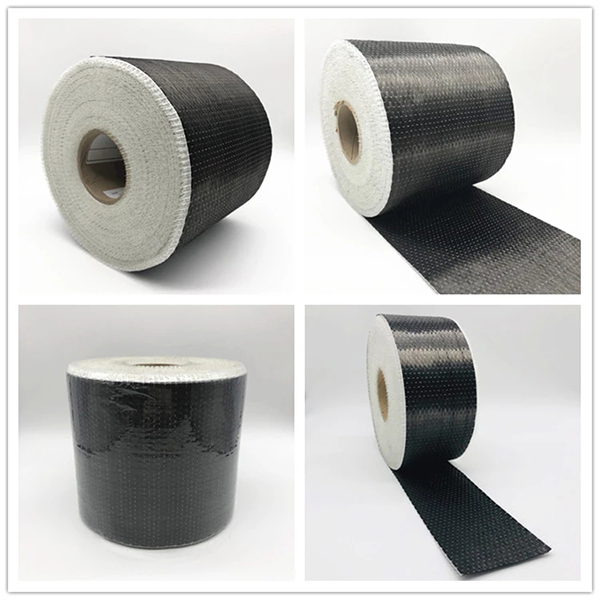

Continuous knitting, no beating, no pilling – no loss of mechanical properties

Lighter weight – a single tow weighs only 0.8g per meter, and its density is only 1 / 4 of that of steel

Carbon cloth tight, smooth surface, easy to penetrate and paste, conducive to performance

Positive weft insertion, point-to-point handover, so that each bundle of yarn tension tends to be consistent

Reduce the strength loss of carbon fiber to a greater extent

Features

1. light weight, can operate in a narrow space, the construction process is not affected

2. high strength, can be flexibly used in bending, shear and compression engineering structure

3. has excellent flexibility and can wrap complex shape components

4. meet the requirements of alkali resistance and chemical corrosion resistance of various component surfaces (bridge, tunnel, slab, beam, column, ventilation barrel, pipe, wall, etc.)

5. can reuse the fabric and cover it smoothly; it has little effect on decoration and long storage life; it has long allowable operation period, and there are some differences in environment before, during and after operation

6. has good high temperature resistance, creep resistance, wear resistance and seismic resistance

Why choose us

1. flatness

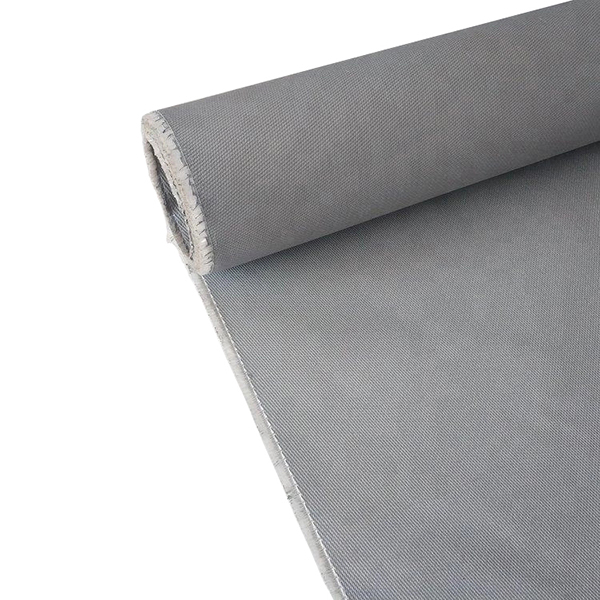

The surface flatness of carbon fiber cloth determines whether the carbon cloth is easy to penetrate and paste

And the carbon cloth can only play its function by sticking firmly

2. strength tension

Only when carbon wires are evenly distributed and each carbon wire is stressed can the strength of carbon cloth be fully exerted. Otherwise, the strength is poor

3. equipment

Advanced equipment not only has large output, but also can customize different width carbon fiber cloth to ensure stable quality in weaving process

Application

1) Reinforcement of building

2) Beam and column fracture reinforcement

3) Seismic strengthening by adding stories

4) Maintenance and reinforcement of viaduct and Bridge

5) Shear wall door opening reinforcement

6) Fracture reinforcement of balcony root

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for OEM manufacturer Carbon Fibre Cloth Suppliers - Purple Carbon Fiber Fabric – Chengyang , The product will supply to all over the world, such as: Jamaica, El Salvador, France, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one's detailed specifications.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.